振动是机电行业比较常见也是比较复杂的问题,对于离心泵来说,遇到振动过高,分析总结大致有以下几种情况:

Vibration is a more common and more complex problem in the mechanical and electrical industry, for centrifugal pumps, when the vibration is too high, the analysis and summary are roughly the following situations:

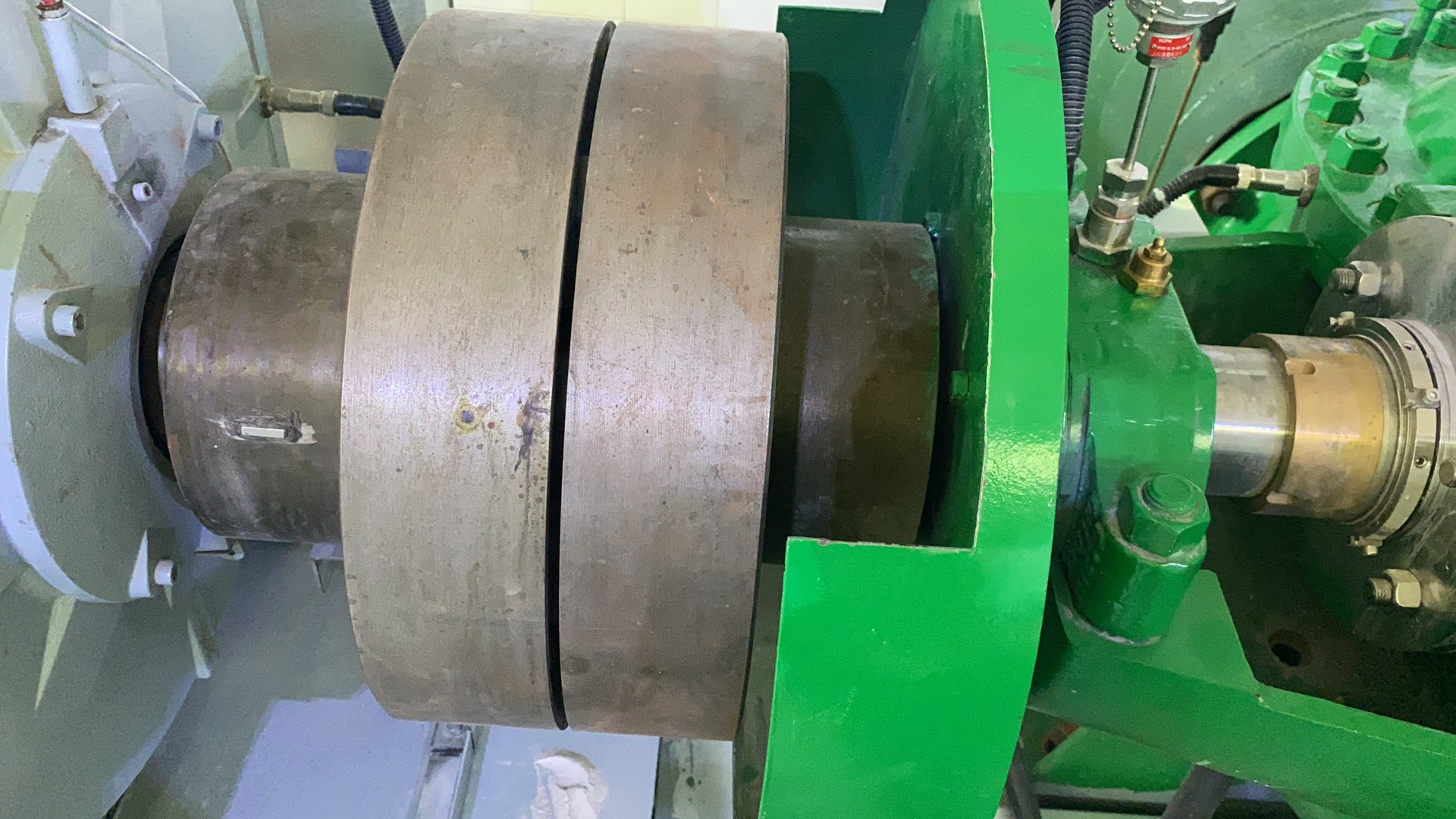

1,管路设计不合理,进出口管路弯头离泵太近,会导致管路应力以及紊流的出现,图片如下图:

The pipeline design is unreasonable, and the elbow of the import and export pipeline is too close to the pump, can cause pipe stress and turbulence,The picture is as follows:

2,轴承磨损或润滑不良。Bearing wear or poor lubrication.

3,有松连接和松配合的存在,比如联轴器的螺栓没有锁紧,或轴承锁紧螺母松,或者轴承室与轴承配合松等。

There is a loose connection and loose fit, such as the coupling bolt is not locked, or the bearing lock nut is loose, or the bearing chamber is loose with the bearing.

4,水泵安装时对中不好,电机有软脚的存在。

When the water pump is installed, the alignment is not good, and the motor has soft feet.

5,入口滤网堵,进水不足,出口背压不足,流量过高,泵在超负荷运行,汽蚀余量不足,导致汽蚀引起振动大。

The inlet filter screen is blocked, the inlet water is insufficient, the outlet back pressure is insufficient, the flow rate is too high, the pump is in overload operation, and the cavitation allowance is insufficient, resulting in large vibration caused by cavitation.

6,变频运行时,在特定频率出现超高的振动,泵和电机一起振动大,可能是产生了共振现象。需要做的是改变运行的频率或者改变泵转子的动平衡精度,还有改变结构的刚性,通过给底座灌浆,焊接加强筋板等措施改变泵转子的自身频率。

When the frequency conversion operation, there is ultra-high vibration at a specific frequency, and the pump and the motor vibrate greatly together, which may be a resonance phenomenon. What needs to be done is to change the frequency of operation or change the dynamic balance accuracy of the pump rotor, as well as change the rigidity of the structure, by grouting the base, welding reinforcement plate and other measures to change the frequency of the pump rotor itself.